Agriculture in Cold Climates

The use case is located in the provinces of Västerbotten and Norrbotten, Sweden. It is active specifically in the areas of Djupliden in Skellefteå and HS Agro Park in Piteå. Agriculture in these areas is largely focused on milk and meat production, and a larger portion of arable land is utilised for ley cultivation compared to Sweden as a whole.

📍 Location: Öjebyn Agro Park near Piteå; a farm near Skellefteå, Norrbotten; Västerbotten, Sweden

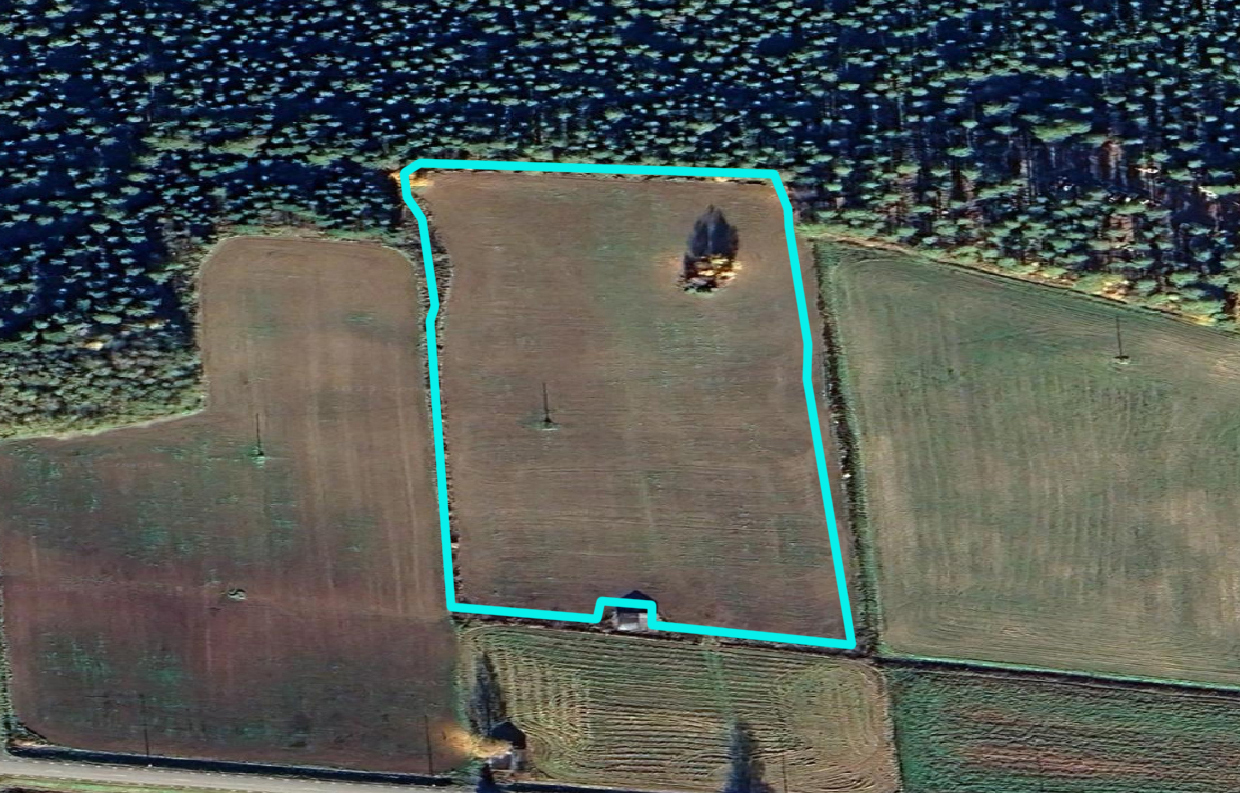

🌾 Area: 15 ha

🌡️ Climate: Cold

🌱 Bio-based products: Animal feed, biogas, biodiesel

The Main Challenges

The Swedish use case is situated in the northern regions of Västerbotten and Norrbotten, where cold temperatures and short vegetation periods create significant challenges for agriculture. The growing season in these regions is defined by an average daily temperature exceeding 5°C and lasts only 139 days, well below the 180-day threshold that defines marginal areas. The accumulated heat sum reaches approximately 900°C, far short of the 1500°C minimum typically needed for reliable oil crop development.

These climatic conditions limit the types of crops that can be grown, while long distances between farms and infrastructure add complexity to logistics and cooperation. Additionally, the local population is declining and ageing, which reduces labour availability and increases the pressure on existing rural services.

Socioeconomic factors

Population – The region exhibits a low population density, with a predominantly elderly population. In the last 50 years the population structure has changed significantly with a large growth in the number of older people and a sharp decrease in the number of younger people.

Long distances – A specific challenge that the two use case regions have to address is the long distances. This challenge is particularly prominent in the rural areas of these regions, while the distances between towns along the coast are relatively shorter.

Solution within MarginUP!

To address these constraints, the project focuses on establishing and optimising a full value chain for the cultivation and processing of spring turnip rape. This crop is introduced here not only as an oil crop, but also to improve soil qualities when used in rotation with cereals. The crop is suitable for colder climates and complements the region’s feed-dominated farming systems. To minimise risks from pests and diseases, turnip rape is not cultivated more frequently than every five to six years in the same location, a consideration that is also reflected in the mapping and planning process.

In the use case, turnip rape oilseeds are processed to extract oil, which is then converted into biodiesel. This process yields two byproducts: press cake and glycerol. Press cake, the solid residue left after oil extraction, is used as a protein-rich animal feed. Glycerol is utilised in experiments to evaluate its potential for biogas production. This proposed circular approach increases land use efficiency, enhances soil health through crop rotation, and strengthens regional energy and feed autonomy. The project supports both environmental and economic sustainability in marginal agricultural areas.

Stakeholders Engaged

- Research institutes

- Universities

- Technology providers

- Bio-based businesses

- Farmers and rural entrepreneurs

- Beekeepers

- Industry partners

- Public sector organisations

Interest Groups

- Cold-climate farmers across Europe

- Renewable energy developers (biodiesel and biogas)

- Feed and fertiliser producers

- Local cooperatives aiming for rural self-sufficiency

- Circular agriculture advocates

- Regional development agencies in remote areas

Benefits

MarginUp!’s proposed alternative land uses offer various social, environmental, and economic benefits.

Biodiversity enhancement

Circular use of biomass

Replication potential

New regional business models

Implemented actions

A total of 39.5 hectares of turnip rape was cultivated across two separate sites as part of both organic and conventional trials. Oil pressing and biodiesel production were initiated, alongside feed testing and glycerol valorisation. Improved agricultural practices, including enhanced weed control and optimised sowing depth, were also implemented.

Timeline

First cultivation (10 +1.5 ha in Piteå and Skellftea) and oil press installed in Piteå. The harvest failed, and changes were applied. An extra harrowing was done, less fertiliser was used, and the sowing depth was changed.

Cultivation expanded (13 ha), 1150 litres of oil produced and first biodiesel batches completed.

Cultivation (15 ha) and 4000 litres of oil produced. Biodiesel production (3000 litres) to be tested in trucks and farm machinery, and press cake to be tested as feed (2000 kg tested) and glycerol for biogas trials.

Full system to be demonstrated in Öjebyn Agro Park.

Replication Potential

This case is well-suited for replication in other cold or marginal agricultural regions across Europe. Its decentralised structure makes it adaptable to smaller-scale operations where access to large processing facilities is limited. The integration of fuel, feed, and fertiliser by-products into a single circular model offers a replicable pathway toward rural resilience and increased self-sufficiency in energy and agriculture.